8 Apr 2025

Establishing a Robust LOTO Program

Creating an effective Lockout/Tagout (LOTO) program isn’t just about writing a procedure and storing it in a binder. It’s about establishing a living, breathing system—one that becomes an integral part of your facility’s safety culture. OSHA’s regulation 29 CFR 1910.147(c)(4) emphasizes this point clearly: employers must develop, document, and utilize procedures for the control of hazardous energy during servicing and maintenance.

But success doesn’t come from compliance alone—it requires consistency, engagement, training, and accountability. A well-framed LOTO program combines technical clarity, workplace discipline, and human responsibility to keep workers safe.

As safety expert Eleanor Everet once said:

"Safety is not a gadget but a state of mind."

In the context of LOTO, that state of mind means never assuming a machine is safe—until you’ve locked it, tagged it, and verified it.

The 7 Core Steps of Lockout/Tagout – Explained in Practice 🛠️

Each stage plays a critical role in preventing injuries and fatalities. Here, we break down the 7 core steps of LOTO into practical actions that align with real-world scenarios and OSHA 1910.147 compliance.

1. Preparation ✅

Identify equipment, energy sources, and potential hazards.

OSHA Ref: 1910.147(c)(4)(ii)(A) 📌

Before any servicing work is performed:

- The authorized employee must identify all energy sources (electrical, mechanical, pneumatic, hydraulic, chemical, thermal, etc.).

- They must understand how energy is controlled and which isolation points must be used.

- Refer to the machine-specific LOTO procedure to prepare tools and devices accordingly.

2. Notification 📣

Inform all affected employees of the shutdown process.

OSHA Ref: 1910.147(c)(5)(ii)(C) 📌

Before starting the lockout/tagout process:

- Notify affected employees—those who operate or work near the equipment—that it will be shut down and locked out.

- Communication must be clear to avoid accidental interaction with the system.

3. Shutdown⏹️

Follow established procedures to power down equipment.

OSHA Ref: 1910.147(d)(1) 📌

Systematic shutdown:

- The authorized employee follows the documented procedure to shut off power in the normal manner.

- Shutdown steps vary by equipment and must be defined in the written procedure.

4. Isolation 🛑

Disconnect the machine from energy sources.

OSHA Ref: 1910.147(d)(3) 📌

Physically isolate all energy sources:

- This includes throwing circuit breakers, closing valves, removing fuses, etc.

- All forms of energy must be considered: primary and secondary.

5. Dissipation 🧯

Release or block any stored energy (e.g., bleeding hydraulic lines).

OSHA Ref: 1910.147(d)(5) 📌

After isolation:

- Stored or residual energy must be relieved, restrained, or made safe.

- Examples:

- Bleed pressure from pneumatic lines

- Release hydraulic pressure

- Discharge capacitors

- Block moving parts

- Examples:

- If energy can reaccumulate, additional controls (restraints, blocking, etc.) must be used.

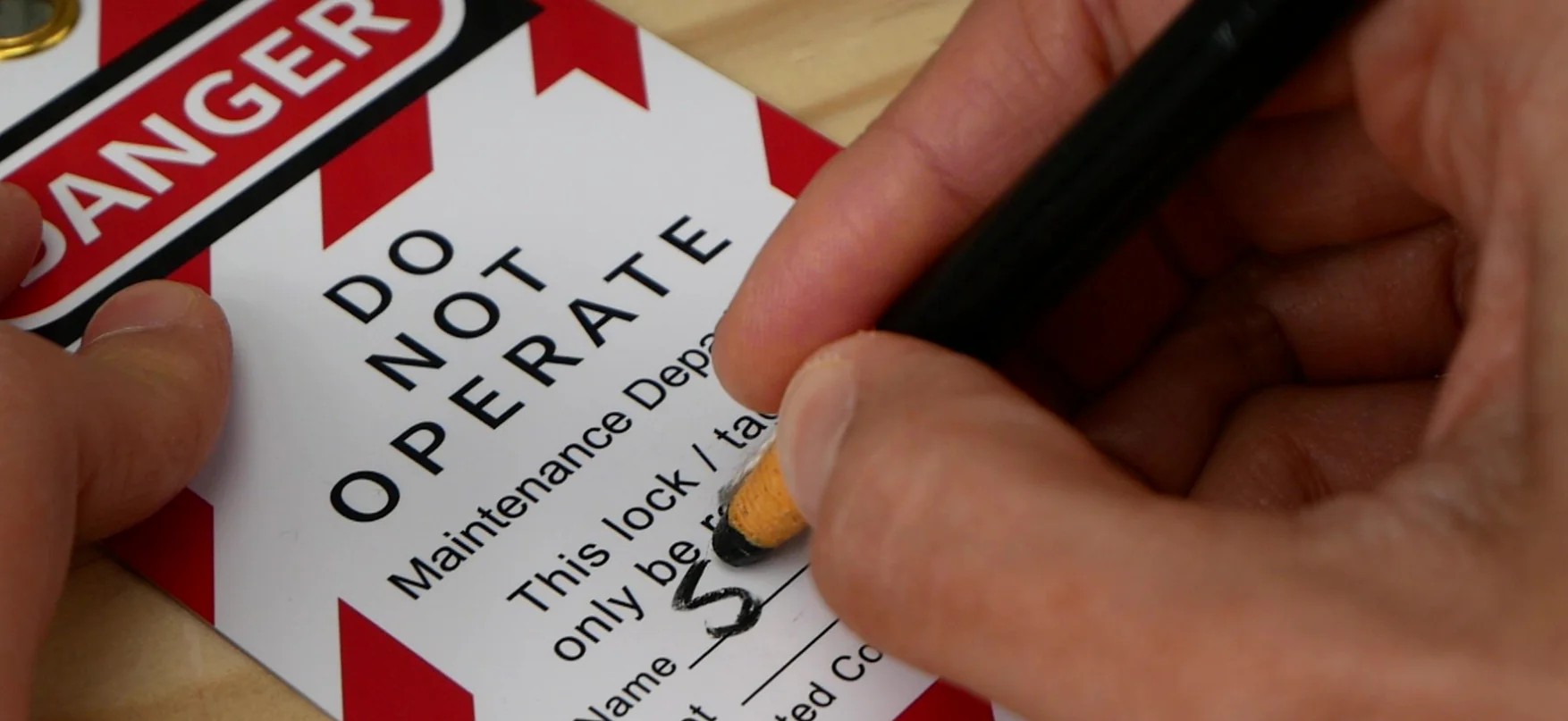

6. Lockout/Tagout 🔐

Secure energy-isolating devices with LOTO locks and tags.

OSHA Ref: 1910.147(d)(4) 📌

Apply lockout/tagout devices:

- Use locks to hold energy-isolating devices in the safe/off position.

- Apply tags with:

- “Do Not Operate” or similar wording

- Name of the person applying the device

- Date/time

- Devices must be:

- Durable: resistant to weather, chemicals, or conditions

- Standardized: in color, shape, or size

- Identifiable: easily traceable to the authorized employee

7. Verification✅

Test and confirm energy isolation before servicing.

OSHA Ref: 1910.147(d)(6) 📌

Before starting maintenance:

- Attempt to start the equipment to verify that all energy has been isolated.

- Test with meters or controls (e.g., pressing the start button) to confirm no motion or power.

- This ensures no residual energy remains and the equipment is safe to service.

Choosing the Right Lockout/Tagout Devices 🔧

Per 1910.147(c)(5), all devices used in lockout/tagout must meet OSHA’s requirements for:

- Durability – Withstand environmental conditions

- Standardization – Be uniform within the facility

- Substantiality – Prevent unauthorized removal

- Identification – Be traceable to the user

Here's a deeper look at the devices:

1. Electrical Lockout Devices🔌

- Used for circuit breakers, plug locks, and electrical disconnects.

- Prevent accidental re-energization of live circuits.

2. Valve Lockout Devices 🔧

- Designed for ball valves, gate valves, butterfly valves, etc.

- Secure the valve in the off position to stop fluid or gas flow.

3. Multi-Purpose Cable Lockouts 🔗

- Versatile for securing multiple devices or hard-to-fit energy sources.

- Ideal when dealing with unusual or complex configurations.

4. Padlocks & Tags 🔒

- Each authorized employee must use their own personal lock and tag.

- Locks should be keyed uniquely (one key per lock).

5. LOTO Boxes 📦

- Used in group lockout operations.

- A supervisor locks out all points and places keys inside a lockbox.

- Each worker attaches their personal lock to the box—equipment stays locked until the last person removes their lock.

Strengthening Your LOTO Program with OSHEPRO 🧠

Standardizing Procedures✔️

- OSHEPRO's powerful tool TRACI allows companies to digitally manage LOTO protocols, ensuring each procedure is:

- Written clearly

- Easily accessible to authorized employees

- Reviewed and approved regularly

Facilitating Annual Audits 📝

- OSHA requires annual inspection of each procedure (1910.147(c)(6)).

- TRACI can schedule, track, and document audits to ensure no procedure is missed.

Enhancing Safety Culture 🙋♂️

- Involving employees in reviewing and practicing LOTO fosters awareness.

- Powerful software applications like TRACI make it easier to log feedback, conduct retraining, and assign corrective actions.

Your Next Step: Turning Procedure into Practice 📌

Lockout Tagout is more than a regulatory requirement—it’s a critical component of workplace safety. With OSHA’s stringent enforcement and the significant risk posed by hazardous energy, every organization must prioritize the development and execution of a comprehensive LOTO program.

A well-framed LOTO program is not just about locking equipment—it’s about:

- Consistent procedures

- Informed and trained employees

- Using the right tools

- Regular verification and audits

Integrating technology, like OSHEPRO, helps move LOTO compliance from just meeting OSHA rules to creating a culture of proactive safety.

By staying compliant, conducting regular audits, and utilizing advanced safety tools like OSHEPRO, businesses can ensure a safer work environment while avoiding costly penalties.

For further guidance, visit the official OSHA website: OSHA Control of Hazardous Energy.

.png)

.png)

.png)

.jpg)