.png)

1 Aug 2024

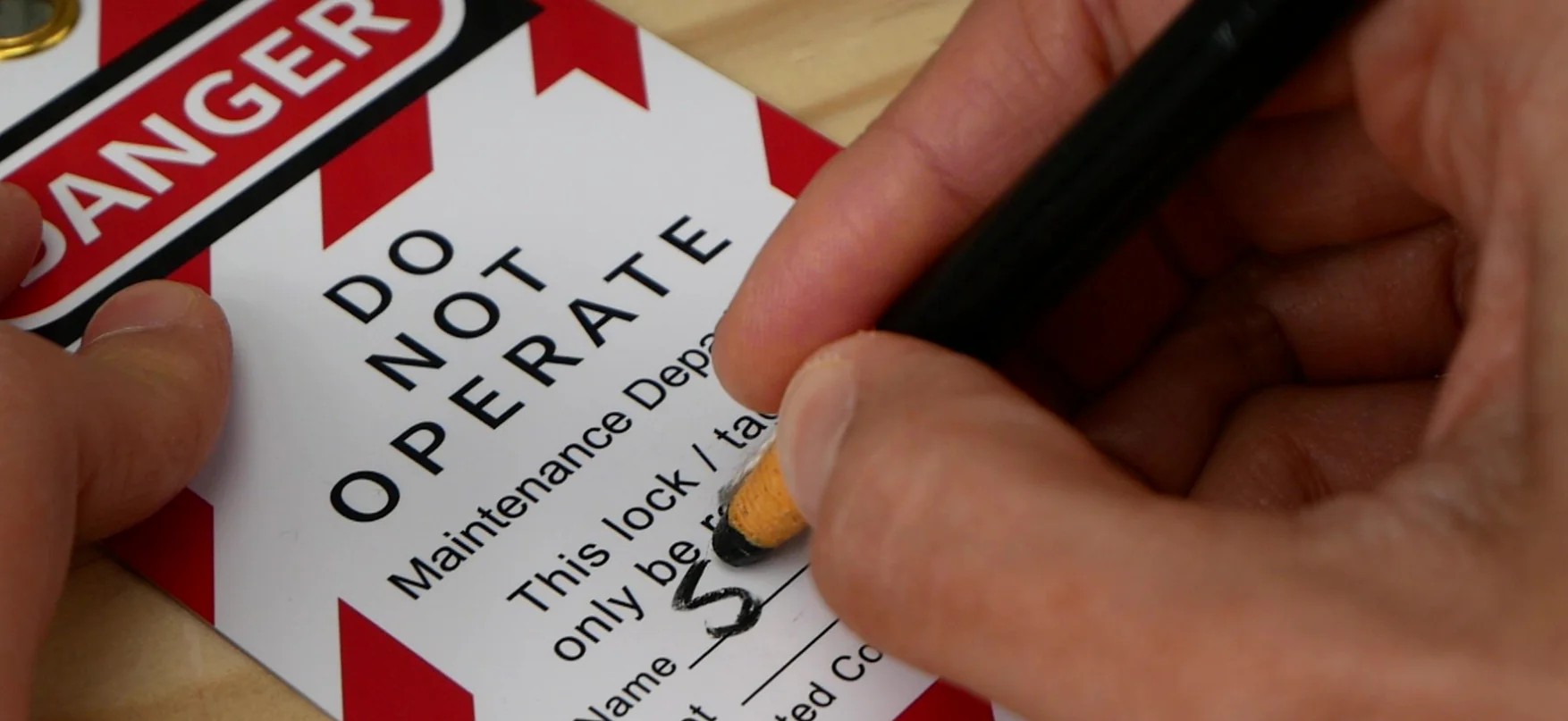

In the pursuit of workplace safety, the Hierarchy of Hazard Control (HOC) is a powerful tool. However, the true potential of HOC lies in its reapplication—taking successful solutions and extending them to similar risks across the organization. This approach not only enhances safety but also optimizes resources. Let’s explore how to effectively utilize and reapply HOC while avoiding common pitfalls.

Effective Strategies for Hazard Control

1. Proactive Hazard Management

Waiting for an accident to happen before taking action is a recipe for disaster. Regular inspections and proactive measures are essential. Identifying potential hazards early allows you to implement controls before they cause harm, creating a safer work environment from the start.

2. Follow the Hierarchy’s Sequence

Jumping straight to the easiest solution, like PPE, is a common mistake. Start with elimination and substitution, the most effective methods. These approaches tackle hazards at their source, providing robust protection. If these options are not feasible, move to engineering controls, then administrative controls, and finally PPE.

3. Invest in Sustainable Solutions

Quick fixes like PPE may seem cost-effective, but they often address only symptoms, not causes. Investing in long-term solutions like elimination, substitution, and engineering controls can prevent hazards from recurring, saving money and improving safety in the long run.

4. Regularly Review and Reapply Controls

Once a control measure is in place, it’s important to monitor its effectiveness continually. If the hazard persists, reassess and consider alternative solutions. Moreover, reapply successful controls to similar hazards in other areas, maximizing the benefits of your safety initiatives.

5. Engage the Workforce

Your employees have firsthand knowledge of the hazards they face. Involving them in hazard identification and control implementation can lead to more practical and effective solutions. Their participation fosters a culture of safety and shared responsibility.

Avoiding Common Mistakes

1. Incomplete Hazard Identification

Thorough hazard identification is critical. Skipping this step can result in inadequate controls. Conduct comprehensive assessments to understand all potential risks and prioritize the most effective controls based on this information.

2. Neglecting Reapplication

Successful hazard controls should not be confined to their initial implementation area. Identify other areas with similar risks and reapply these successful measures. This approach ensures consistent safety standards across the organization.

3. Ignoring the Need for Updates

The workplace is constantly evolving, and so are its hazards. Regularly updating and reviewing your hazard controls is essential to ensure they remain effective. This ongoing process helps adapt to new risks and changing conditions.

4. Overreliance on Training

Training is crucial but should complement other hazard controls, not replace them. Training alone does not eliminate hazards; it equips employees to handle them better. Ensure that robust control measures are in place to address hazards directly.

5. Poor Communication

Effective hazard control requires clear communication. Ensure all employees understand the hazards, the control measures in place, and any changes to protocols. Clear communication fosters adherence to safety practices and a unified approach to hazard management.

Practical Examples of Reapplication

- Safer Chemical Handling in Labs: If a laboratory replaces a hazardous solvent with a safer alternative, this success should prompt a review of all lab processes to identify other instances where similar substitutions can be made. Reapplying this strategy across the board enhances safety throughout the facility.

- Noise Reduction Across Industries: Installing noise-dampening enclosures around loud machinery can significantly improve worker health. Once proven effective in one area, extend this solution to all noisy areas within the facility to ensure consistent noise reduction.

- Standardizing Patient Handling in Healthcare: Implementing a new patient handling protocol that reduces injuries among nurses should be replicated across all departments and facilities within a healthcare network. This widespread adoption promotes uniform safety standards.

Embrace Reapplication for Enhanced Safety

The true power of the Hierarchy of Hazard Control lies in its strategic reapplication. By continuously identifying and extending effective controls to similar hazards, organizations can foster safer, more efficient workplaces. Embrace proactive management, engage your workforce, and make reapplication a cornerstone of your safety strategy to maximize the benefits and create a culture of continuous improvement.

At OSHEPRO, we understand the critical importance of workplace safety and the effective use of the Hierarchy of Hazard Control. Our integrated applications, including TRACI, are designed to help organizations systematically identify, assess, and control hazards. We are committed to helping you achieve these goals with our innovative solutions and dedicated support. Let’s work together to create a safer and more productive work environment.

.png)

.png)

.png)

.jpg)